Effective inventory management is crucial for businesses that deal with physical products. A key tool in this process is the Bill of Materials (BOM), which is a comprehensive list of all the components, parts, and materials needed to produce a product. When managing and tracking these components, using a Bill of Material Excel template can significantly simplify the task. This article will delve into the world of BOMs, explaining their importance, how to create a Bill of Material Excel template, and tips for using it effectively for easy tracking.

Understanding the Bill of Materials

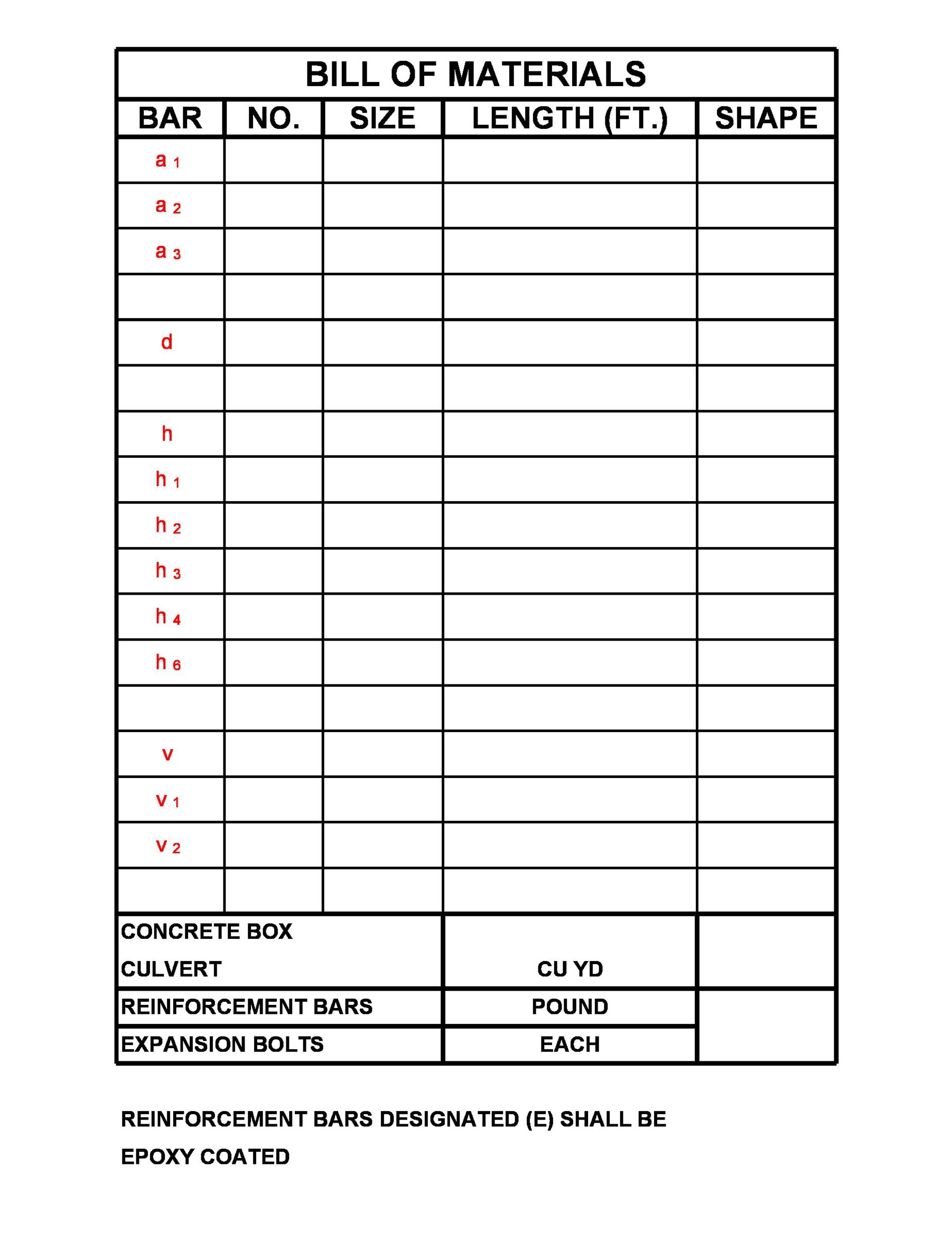

A Bill of Materials is a detailed list of all the raw materials, components, and sub-assemblies required to manufacture a product. It serves as a critical document in the production process, helping manufacturers and suppliers ensure that they have all the necessary components in the correct quantities. BOMs can be categorized into different types, including:

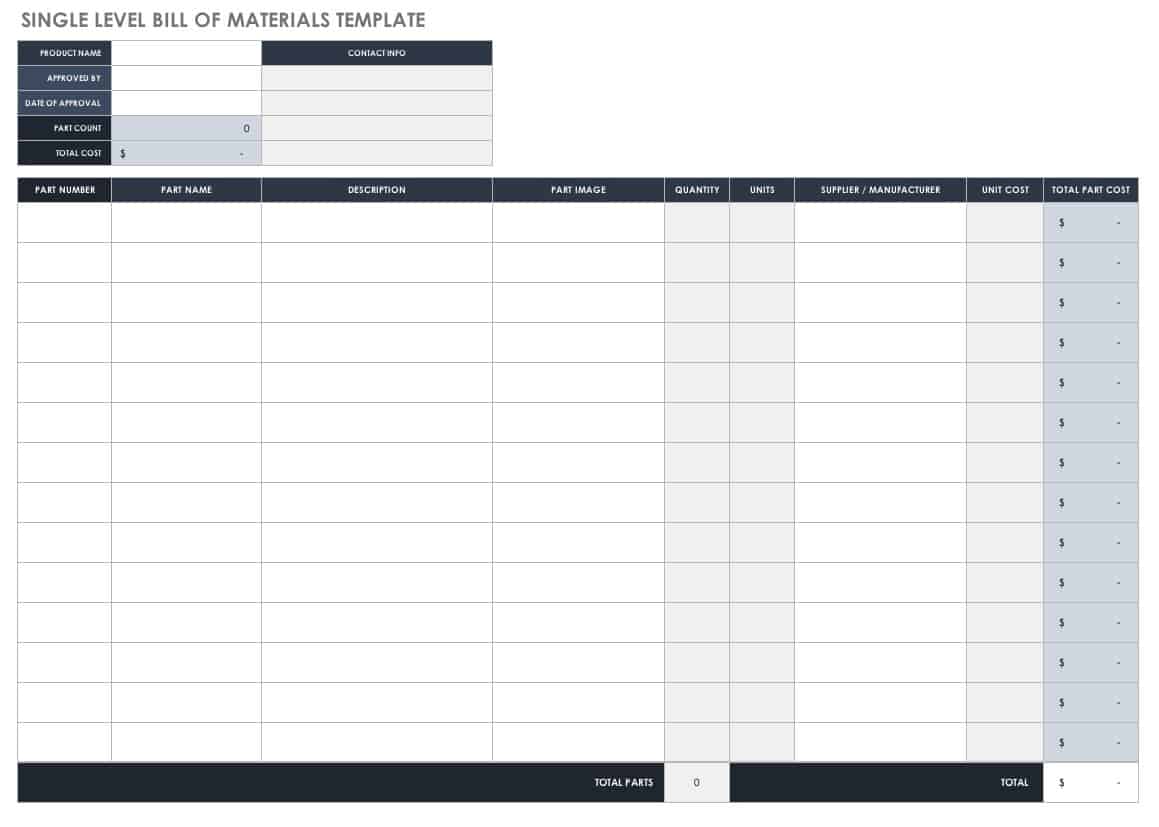

Single-Level BOM

This is the simplest form of a BOM, which lists the components and materials needed for a single product without showing the relationship between them.

Multi-Level BOM

This type of BOM provides a more detailed breakdown, showing the hierarchy of components and sub-assemblies within a product. It's essential for complex products that require various levels of assembly.

Configurable BOM

Configurable BOMs are used for products that can be customized according to specific customer needs. This type of BOM lists various options and components that can be combined to create a customized product.

Why Use a Bill of Material Excel Template?

Using a Bill of Material Excel template offers several advantages over traditional methods of tracking and managing BOMs. Here are some reasons why businesses prefer to use Excel templates:

-

Ease of Use: Excel is a widely recognized and used tool. Most professionals are familiar with its functions and formulas, making it easier to implement and share BOM templates within an organization.

-

Flexibility and Customization: Excel templates can be easily customized to fit the specific needs of a product or production process. Users can add, remove, or modify fields as required.

-

Automatic Calculations: Excel formulas can automatically calculate quantities, costs, and other critical metrics, reducing the risk of human error and saving time.

-

Integration with Other Tools: Excel can integrate with various other tools and systems, such as inventory management software and accounting systems, making it a versatile solution for managing BOMs.

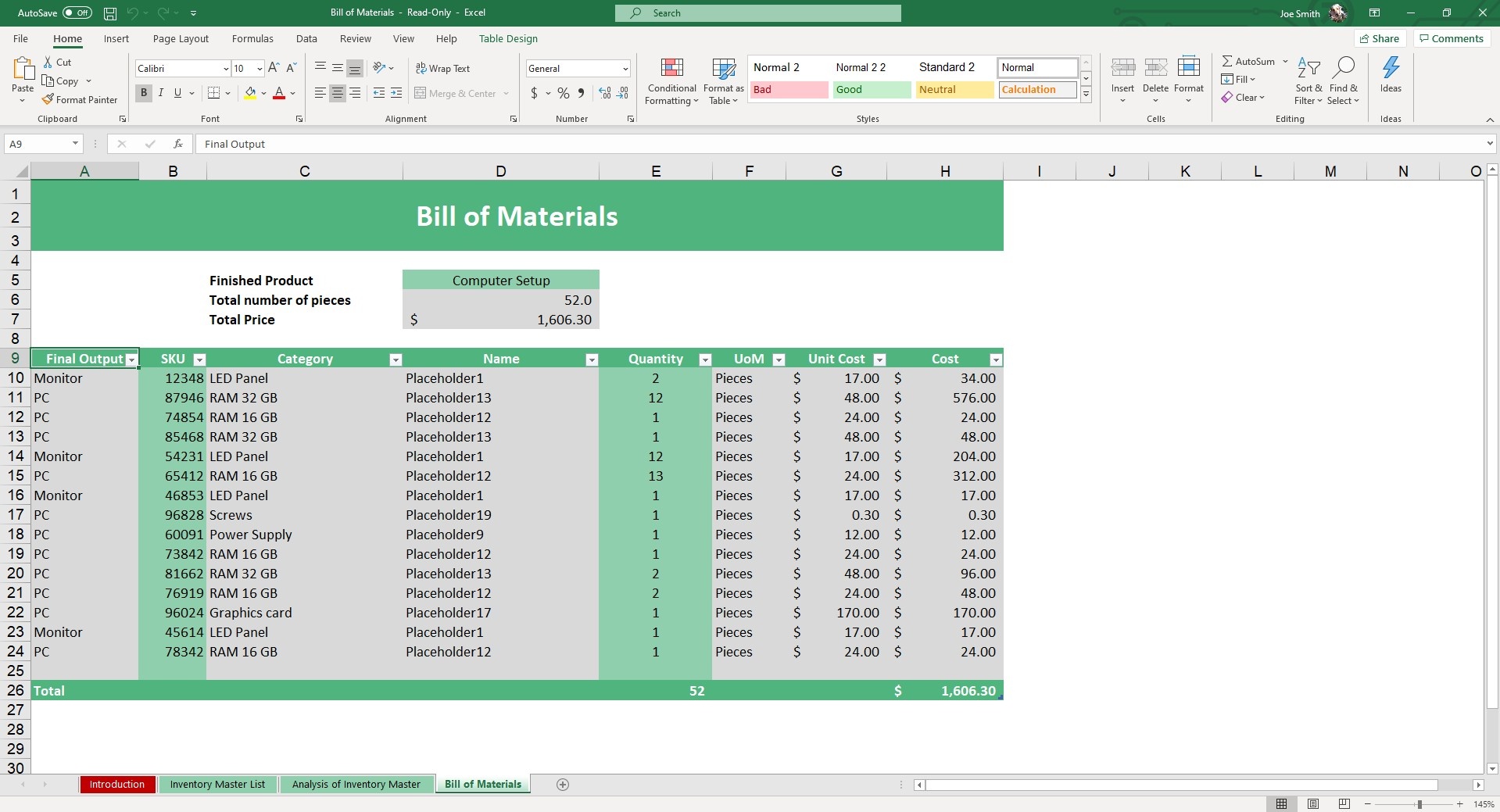

Creating a Bill of Material Excel Template

Creating a Bill of Material Excel template from scratch requires some planning and understanding of your production process. Here's a simplified guide to get you started:

-

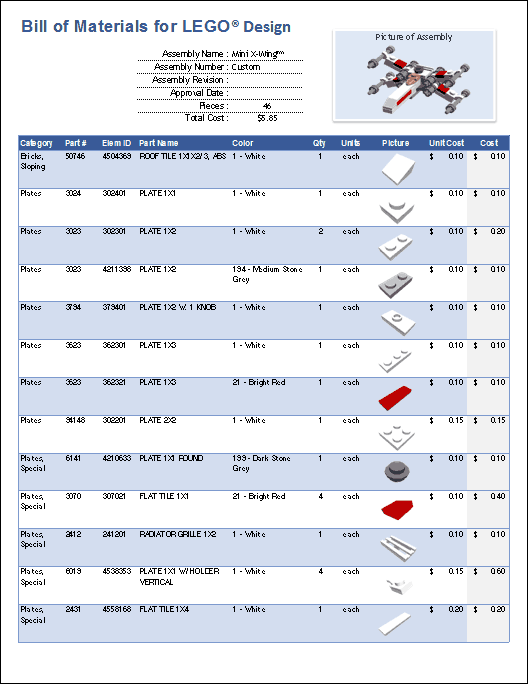

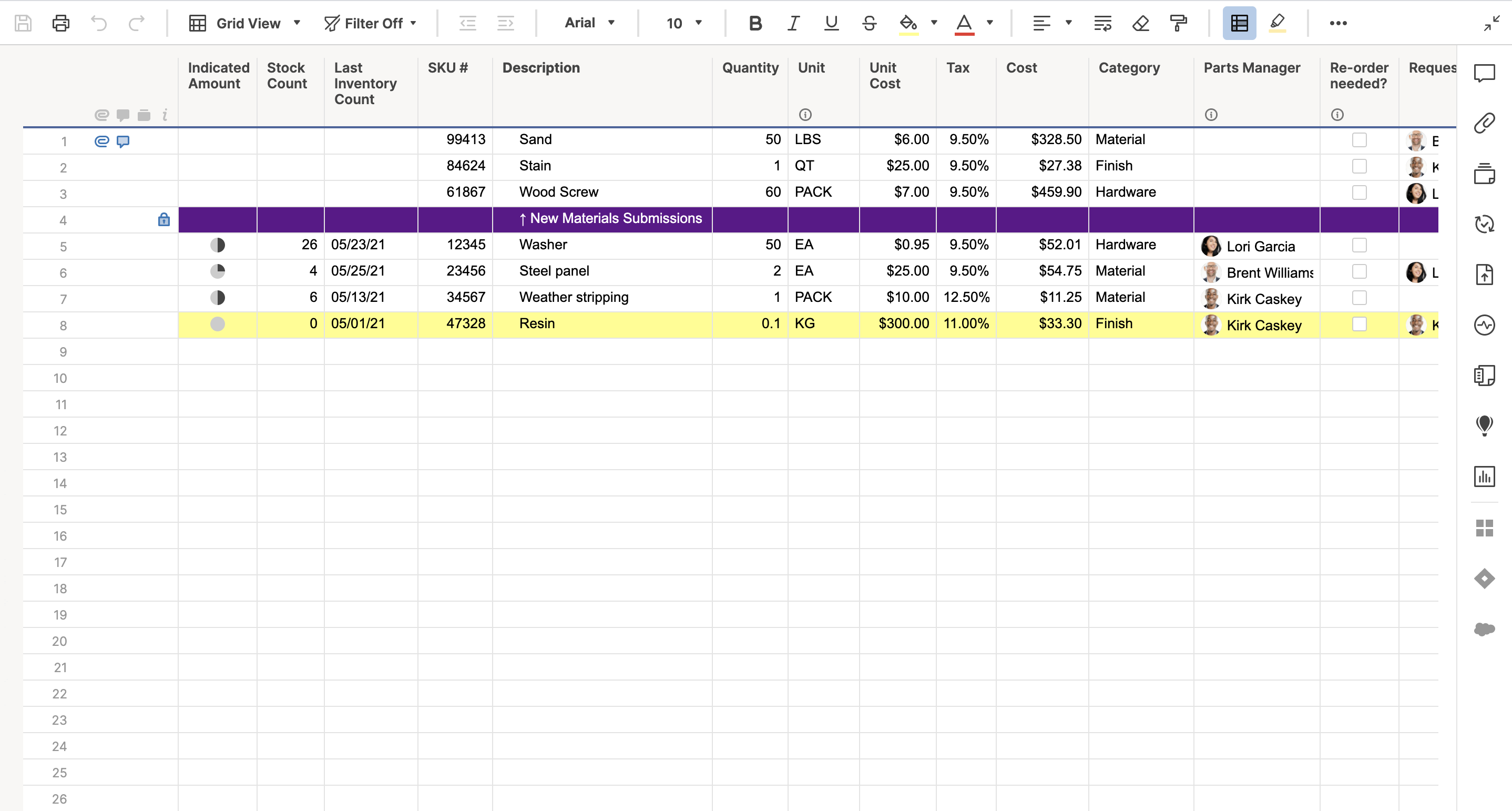

Identify Your Needs: Determine what information you need to track. This typically includes part numbers, descriptions, quantities, units of measure, and costs.

-

Set Up Your Workbook: Create a new Excel workbook. You might want to consider creating separate sheets for different products or categories of components.

-

Design Your Template: Start designing your template by creating a table with the necessary columns. Use headers to identify each column clearly.

-

Add Formulas and Functions: Use Excel formulas to automate calculations such as totals, subtotals, and multiplication for quantities and costs.

-

Format for Readability: Use Excel's formatting options to make your template visually appealing and easy to read. This includes using different colors, fonts, and borders.

-

Test and Refine: Before using your template in production, test it with sample data. Make adjustments as necessary to ensure it meets your needs.

Tips for Using Your Bill of Material Excel Template Effectively

To maximize the benefits of your Bill of Material Excel template, consider the following tips:

-

Regular Updates: Keep your template up-to-date by regularly updating part numbers, costs, and quantities to reflect changes in your production process.

-

Standardization: Ensure that your template is standardized across your organization to avoid confusion and errors.

-

Training: Provide training for all users to ensure they understand how to use the template effectively.

-

Review and Audit: Regularly review and audit your template to identify and correct any errors or discrepancies.

-

Integration with Inventory Management: Consider integrating your BOM template with your inventory management system to streamline ordering and stocking processes.

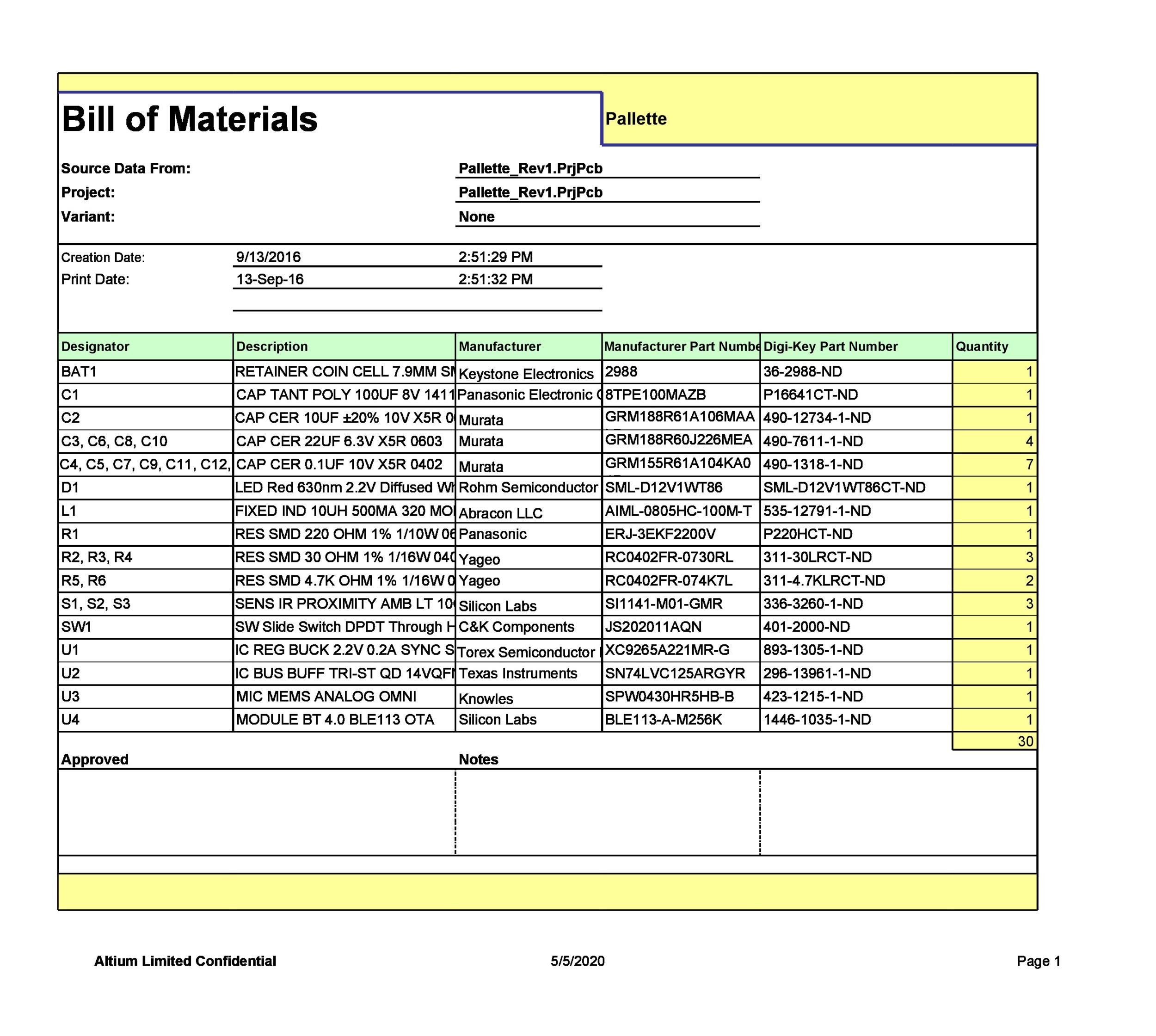

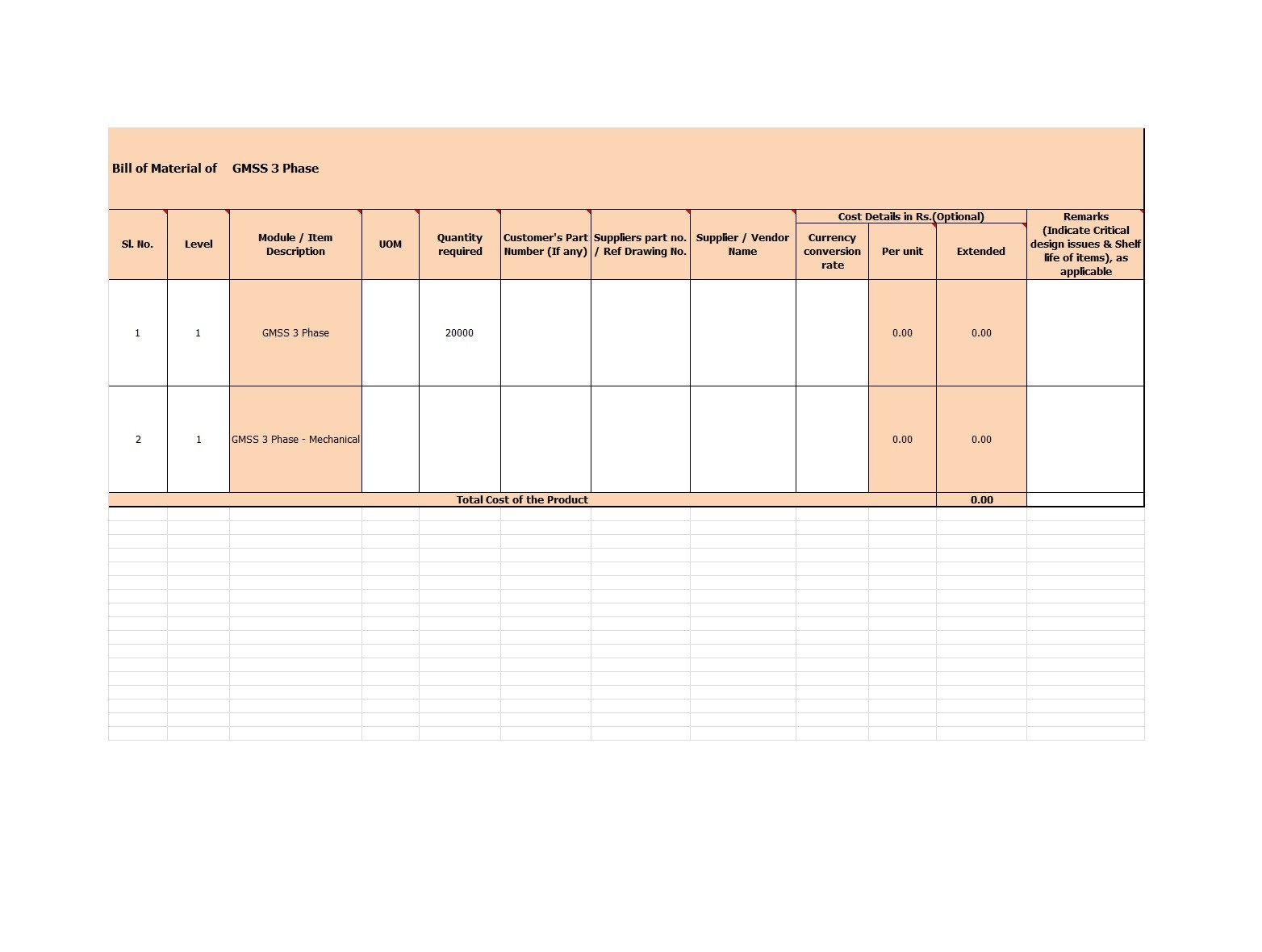

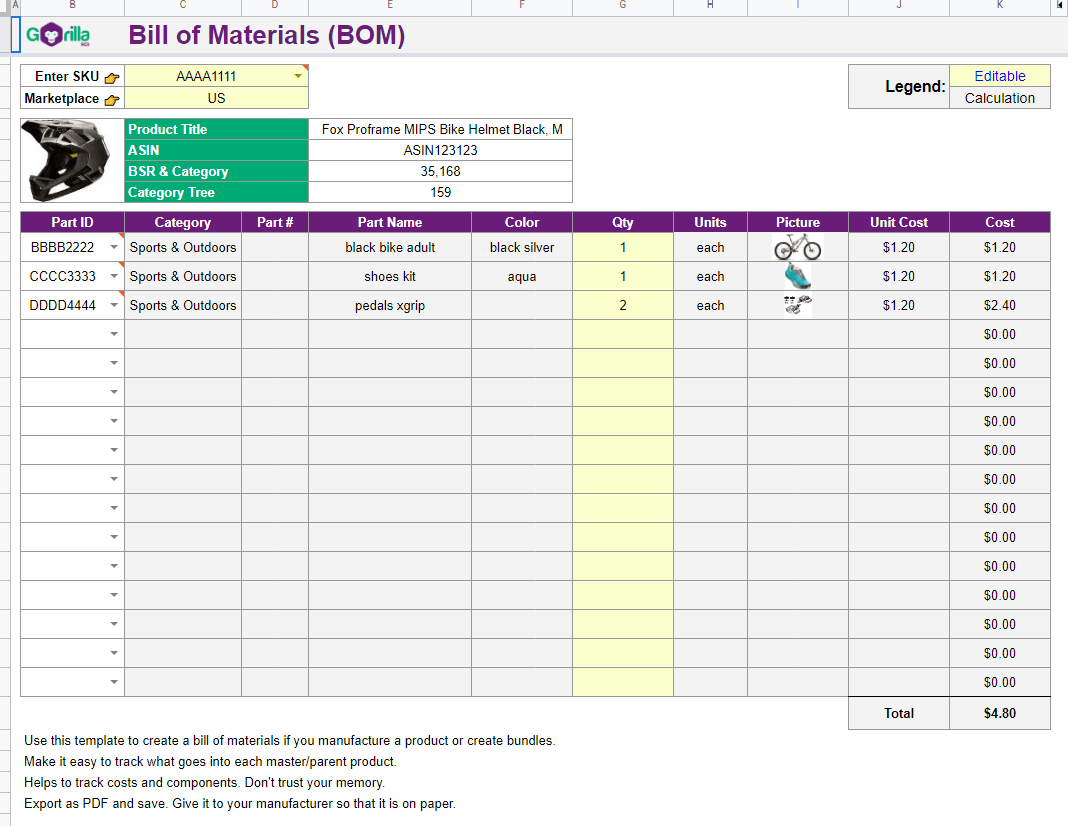

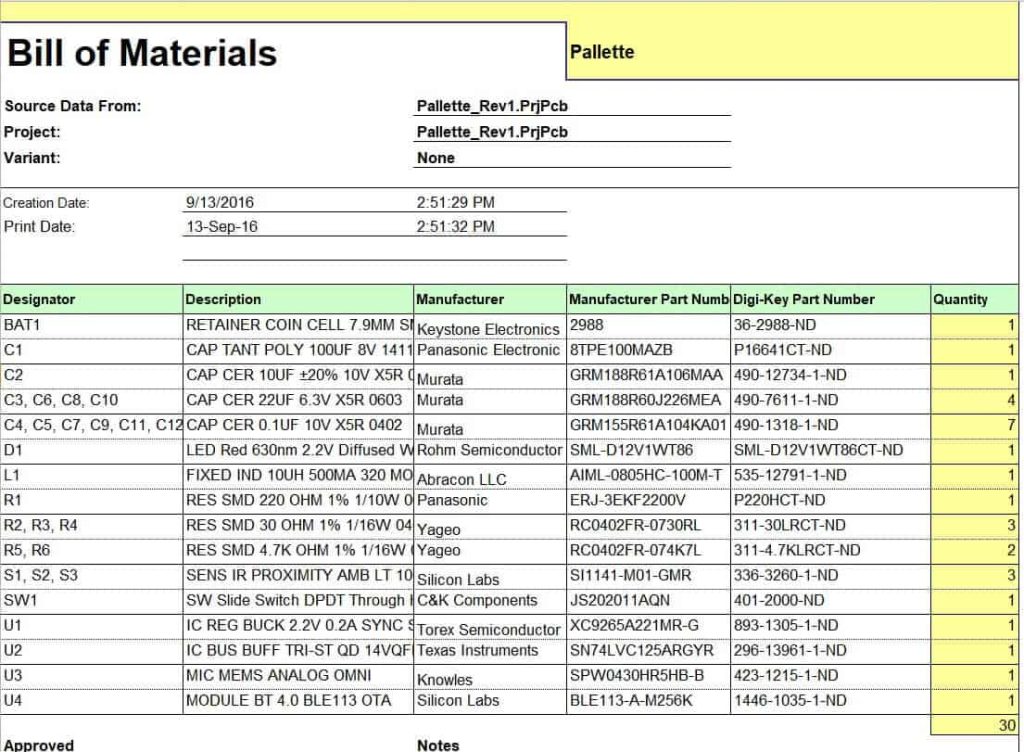

Gallery of Bill of Material Excel Templates

Frequently Asked Questions

What is a Bill of Materials (BOM)?

+A Bill of Materials is a comprehensive list of all the components, parts, and materials needed to manufacture a product.

Why use a Bill of Material Excel template?

+Using a Bill of Material Excel template offers ease of use, flexibility, automatic calculations, and the ability to integrate with other tools.

How do I create a Bill of Material Excel template?

+Create a template by identifying your needs, setting up your workbook, designing your template, adding formulas and functions, formatting for readability, and testing and refining your template.

In conclusion, a well-designed Bill of Material Excel template is indispensable for any business involved in manufacturing or production. By understanding the types of BOMs, the benefits of using an Excel template, and how to create and use one effectively, businesses can streamline their inventory management and production processes. We hope this guide has provided you with the information you need to start improving your production efficiency today. Share your experiences with using BOM templates or ask any questions you might have in the comments below!