The bill of materials (BOM) is a critical document used in manufacturing and production processes to outline the components, materials, and quantities required to produce a product. While there are various software tools available to manage BOMs, many professionals still prefer to use Excel due to its flexibility and ease of use. In this article, we will discuss five essential tips for creating an effective bill of material in Excel format.

Understanding the Importance of a Bill of Materials

A bill of materials is a comprehensive list of components, materials, and quantities required to produce a product. It serves as a critical input for various business functions, including procurement, inventory management, production planning, and cost estimation. An accurate and up-to-date BOM is essential for ensuring that products are manufactured efficiently, cost-effectively, and to the required quality standards.

Tips for Creating an Effective Bill of Material in Excel Format

Creating an effective BOM in Excel format requires careful planning, attention to detail, and a structured approach. Here are five essential tips to help you create a robust and maintainable BOM in Excel:

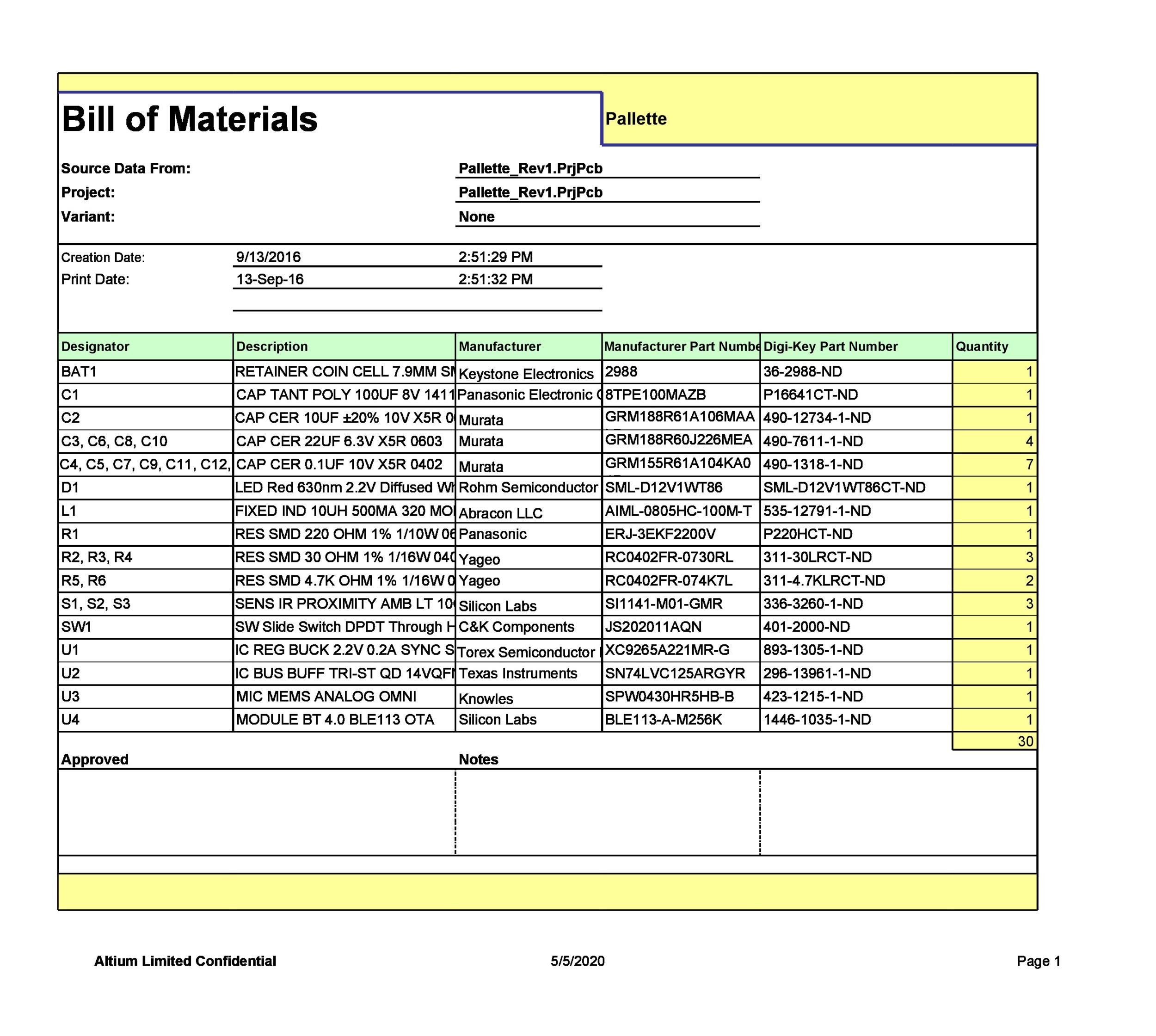

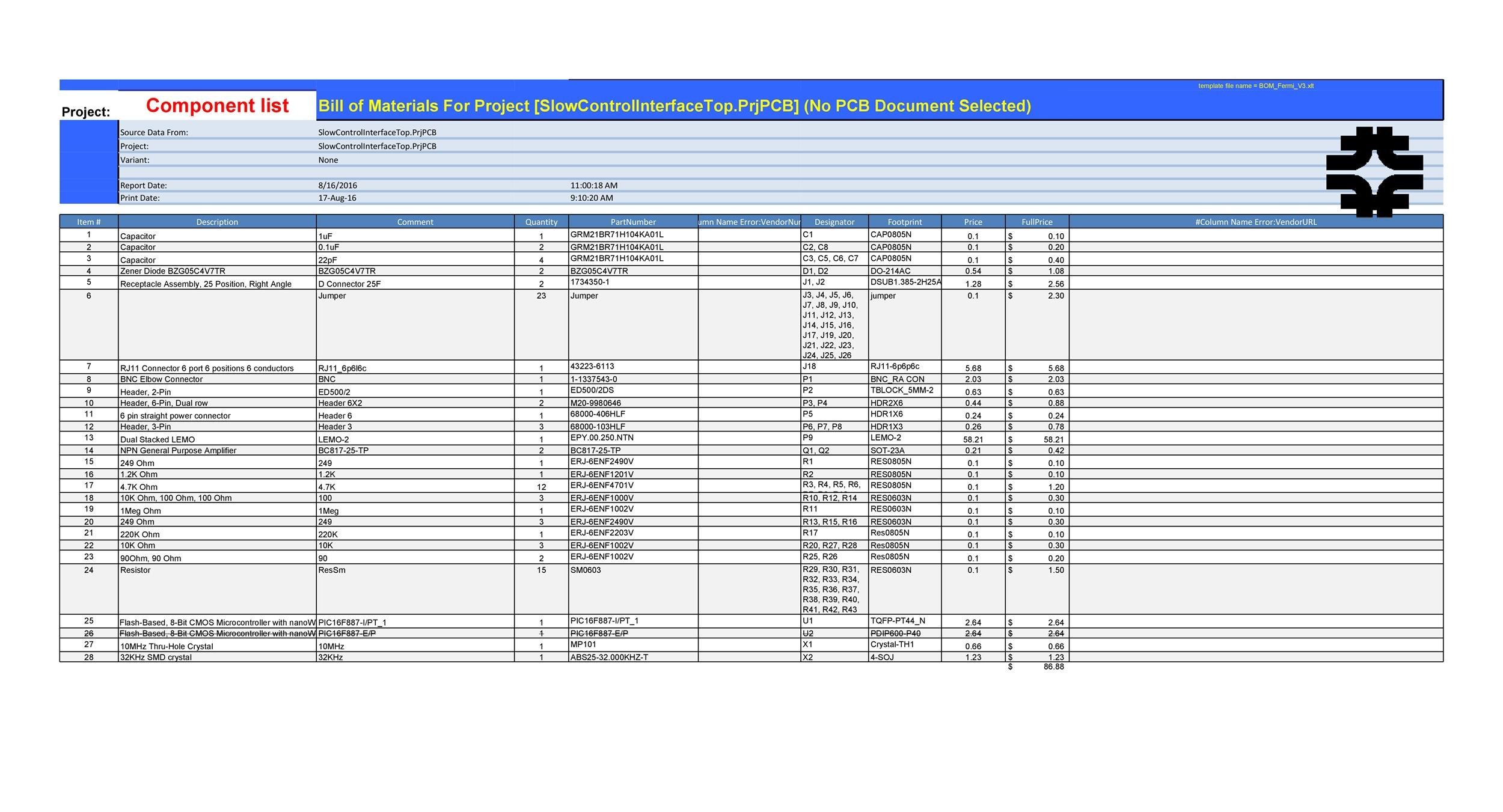

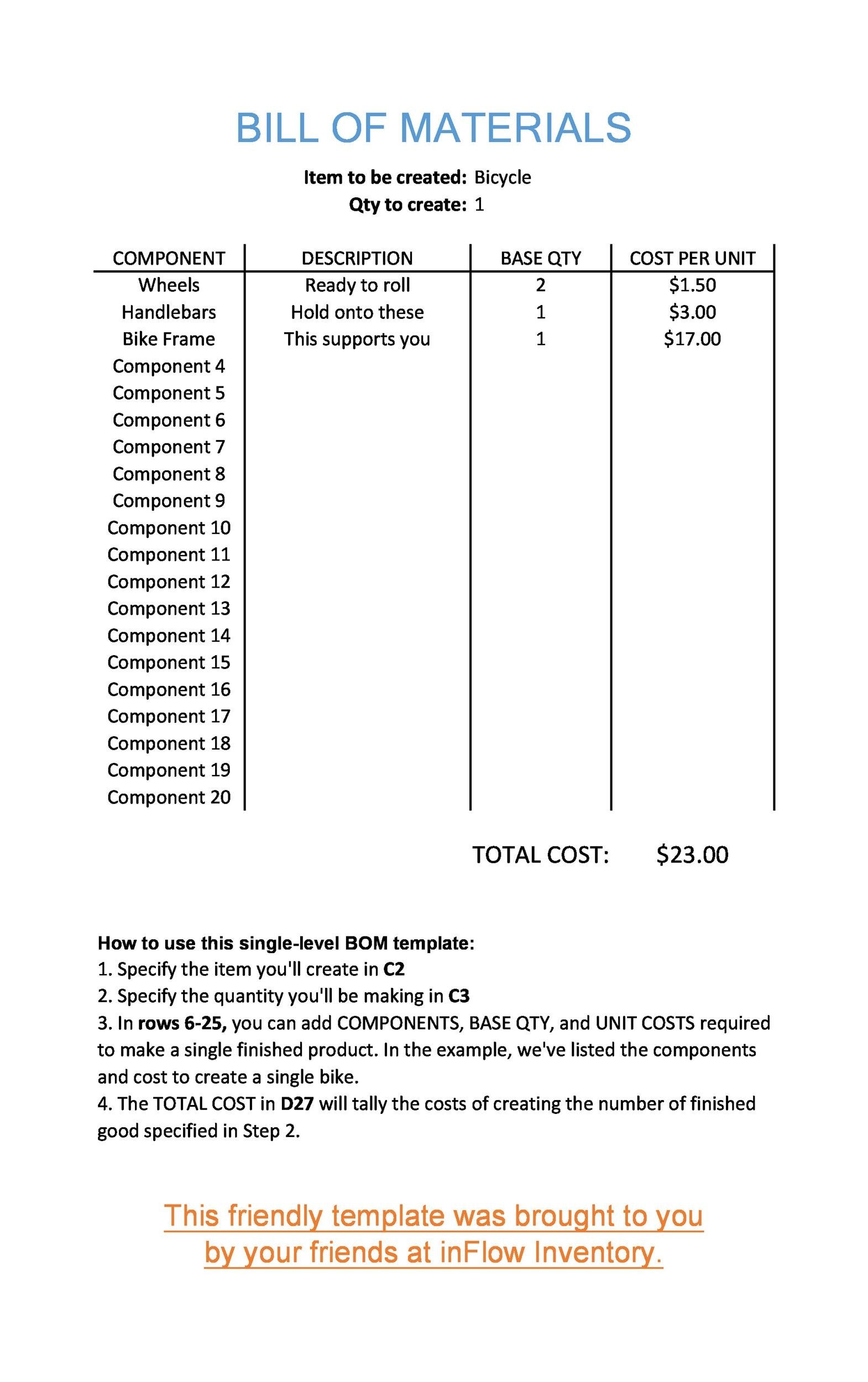

Tip 1: Use a Standardized Template

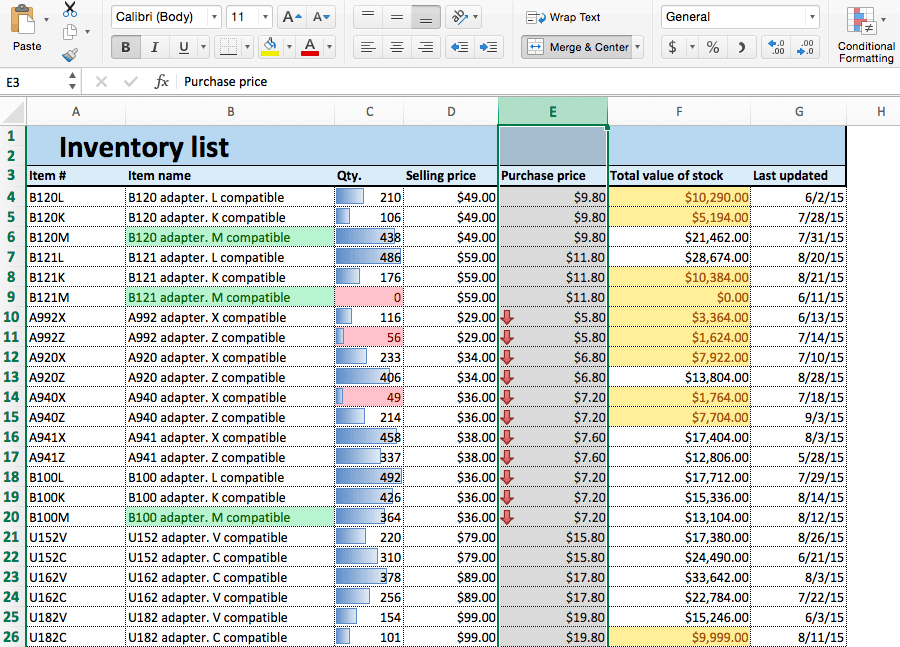

Using a standardized template is essential for creating a consistent and easy-to-understand BOM. A typical BOM template should include the following columns:

- Part number

- Description

- Quantity

- Unit of measure

- Material type

- Supplier information

- Cost

You can customize the template to suit your specific needs, but it's essential to maintain a consistent format throughout the document.

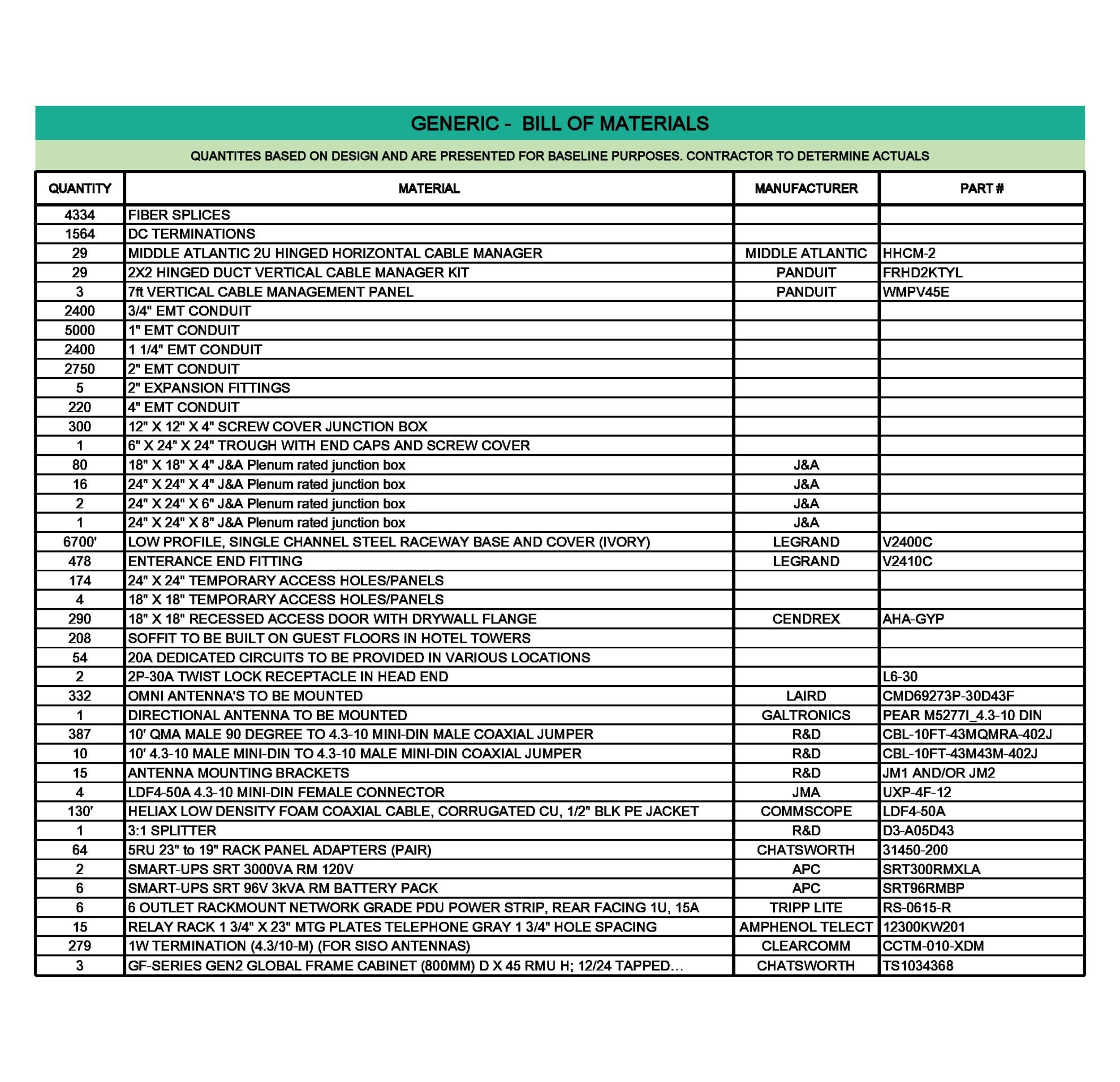

Tip 2: Use Hierarchical Structuring

A hierarchical structuring approach involves organizing the BOM into a tree-like structure, with the top-level component representing the final product and the lower-level components representing the sub-assemblies and individual parts. This approach helps to simplify complex products and makes it easier to manage and maintain the BOM.

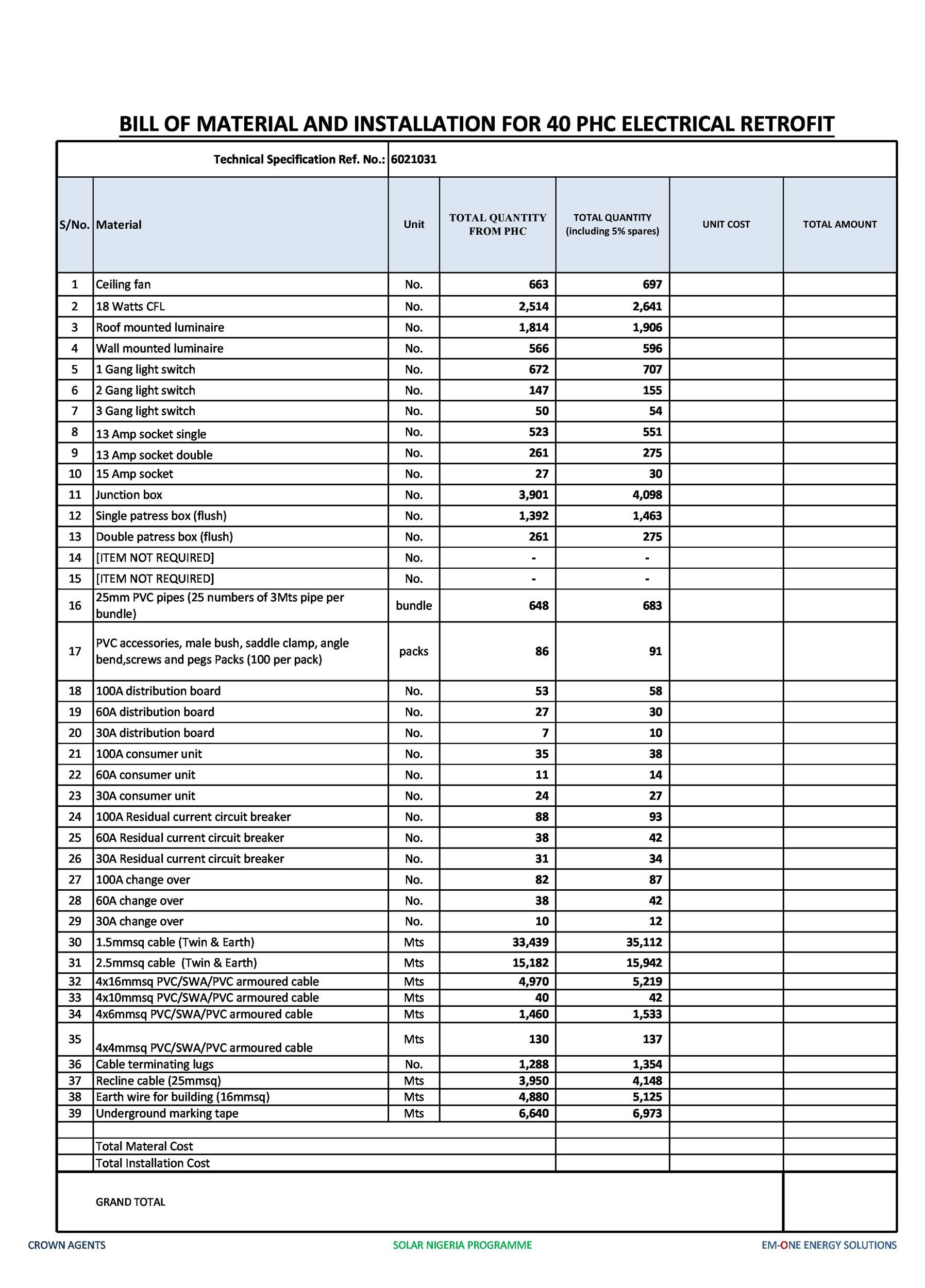

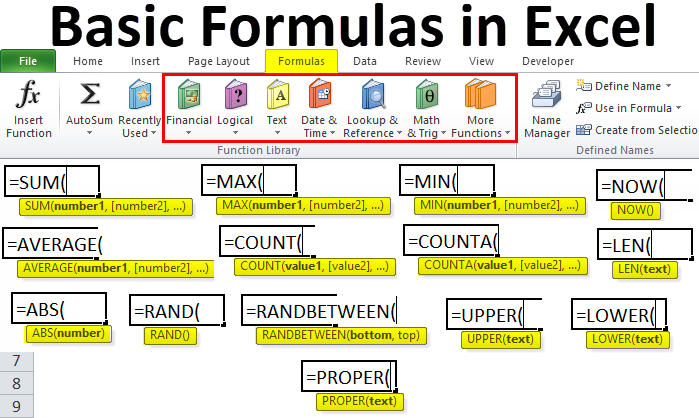

Tip 3: Use Formulas and Functions

Excel formulas and functions can help to simplify complex calculations and reduce errors. You can use formulas to calculate quantities, costs, and other relevant data. Some common formulas used in BOMs include:

- SUM: calculates the total quantity of a component

- PRODUCT: calculates the total cost of a component

- VLOOKUP: looks up data in a table and returns a value

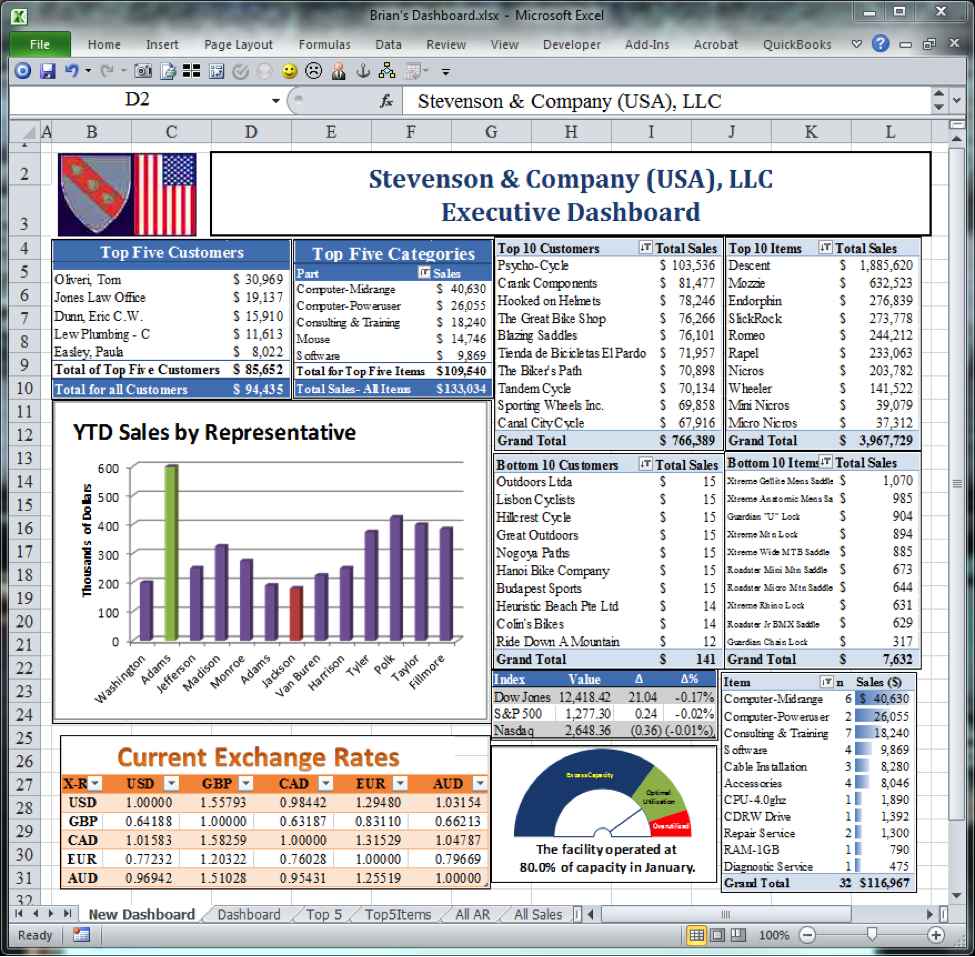

Tip 4: Use Conditional Formatting

Conditional formatting is a powerful feature in Excel that allows you to highlight cells based on specific conditions. You can use conditional formatting to highlight critical components, identify potential bottlenecks, and draw attention to important information.

Tip 5: Review and Update Regularly

A BOM is a dynamic document that requires regular review and updates to ensure accuracy and relevance. You should review the BOM regularly to ensure that it reflects changes in the product design, supplier information, and other relevant data.

Conclusion

Creating an effective bill of material in Excel format requires careful planning, attention to detail, and a structured approach. By using a standardized template, hierarchical structuring, formulas and functions, conditional formatting, and regular review and updates, you can create a robust and maintainable BOM that supports your manufacturing and production processes.

What is a bill of materials?

+A bill of materials is a comprehensive list of components, materials, and quantities required to produce a product.

Why is a bill of materials important?

+A bill of materials is essential for ensuring that products are manufactured efficiently, cost-effectively, and to the required quality standards.

What are the benefits of using a standardized template for a bill of materials?

+Using a standardized template for a bill of materials helps to maintain consistency and makes it easier to understand and manage the document.