Calculating safety stock is a crucial aspect of inventory management, as it ensures that a business has sufficient stock to meet customer demand in case of supply chain disruptions or changes in demand. In this article, we will explore five ways to calculate safety stock in Excel, a popular spreadsheet software used by many businesses.

The Importance of Safety Stock

Safety stock, also known as buffer stock, is a level of inventory that a business maintains to mitigate the risk of stockouts and lost sales. It serves as a cushion against uncertainties in demand and supply, allowing businesses to respond quickly to changes in the market. Without adequate safety stock, businesses may face stockouts, lost sales, and damaged customer relationships.

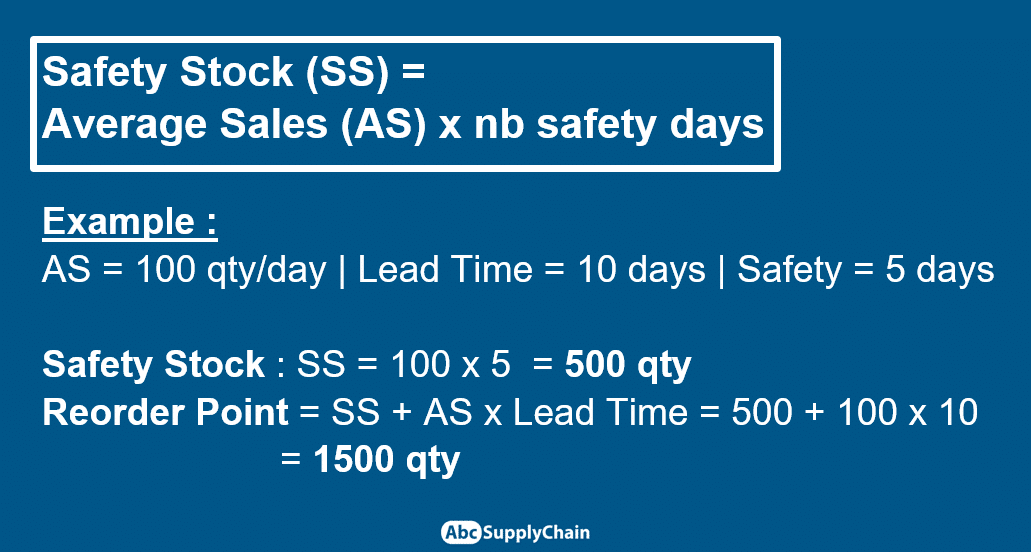

Method 1: Basic Safety Stock Calculation

The basic safety stock calculation involves multiplying the average daily demand by the lead time, which is the time it takes to replenish inventory.

Formula: Safety Stock = Average Daily Demand x Lead Time

Example:

| A | B | |

|---|---|---|

| 1 | Average Daily Demand | 10 |

| 2 | Lead Time (days) | 5 |

| 3 | Safety Stock | =A1*B1 |

Using this formula, the safety stock would be 50 units (10 units/day x 5 days).

Image:

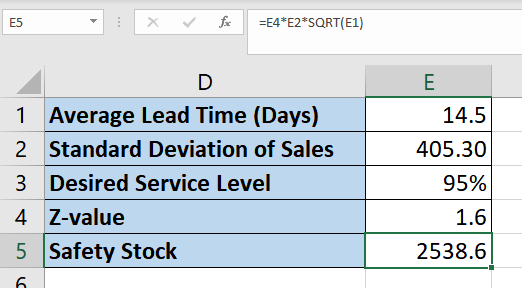

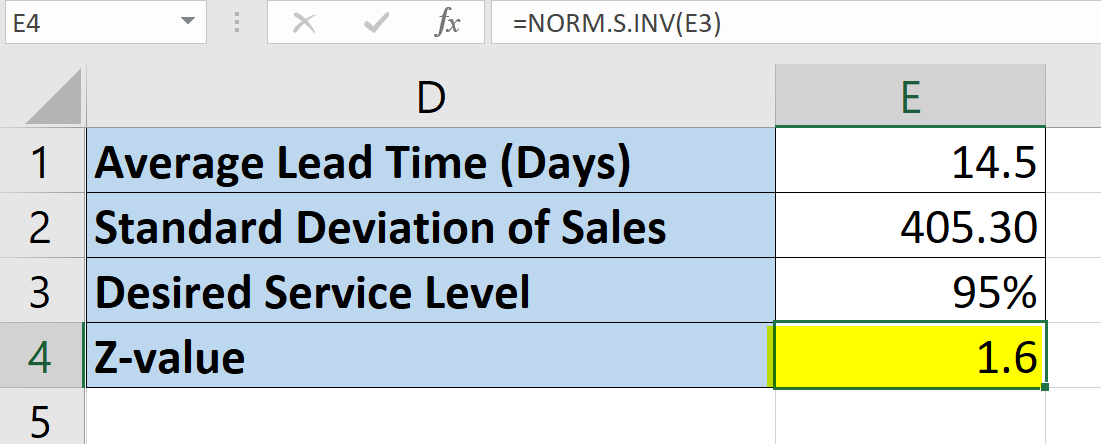

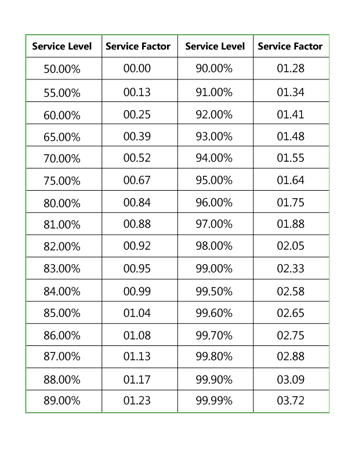

Method 2: Service Level-Based Safety Stock Calculation

This method involves calculating safety stock based on the desired service level, which is the probability of meeting customer demand.

Formula: Safety Stock = (Service Level x Average Daily Demand x Standard Deviation of Demand) / (1 - Service Level)

Example:

| A | B | C | |

|---|---|---|---|

| 1 | Average Daily Demand | 10 | |

| 2 | Standard Deviation of Demand | 2 | |

| 3 | Service Level | 95% | |

| 4 | Safety Stock | =(A1*C1*B1)/(1-C1) |

Using this formula, the safety stock would be 57 units.

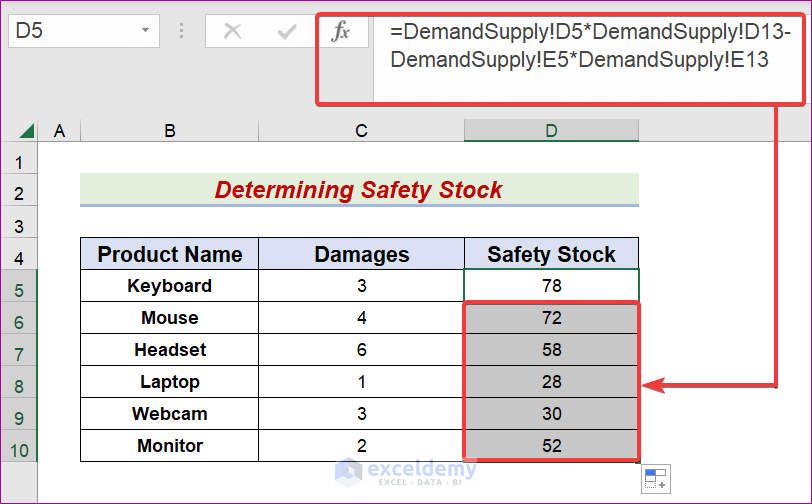

Image:

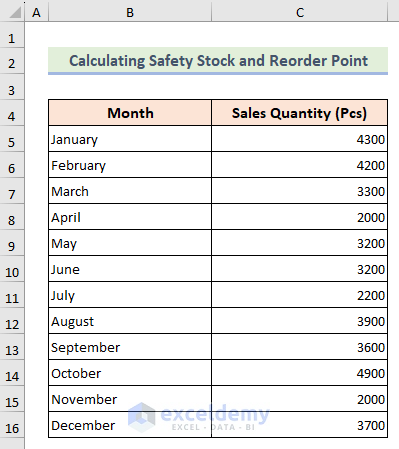

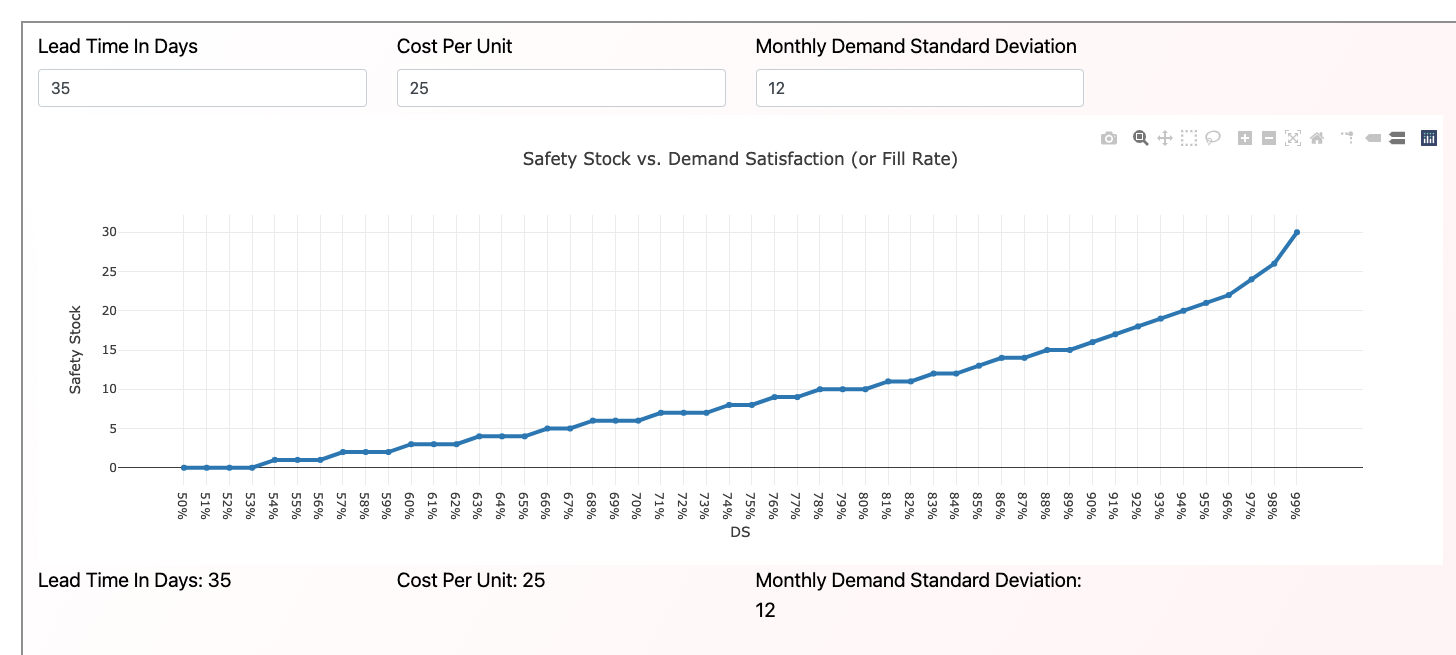

Method 3: Historical Data-Based Safety Stock Calculation

This method involves analyzing historical demand data to calculate safety stock.

Formula: Safety Stock = (Maximum Demand - Average Demand) x Lead Time

Example:

| A | B | C | |

|---|---|---|---|

| 1 | Average Daily Demand | 10 | |

| 2 | Maximum Daily Demand | 20 | |

| 3 | Lead Time (days) | 5 | |

| 4 | Safety Stock | =(B1-A1)*C1 |

Using this formula, the safety stock would be 50 units.

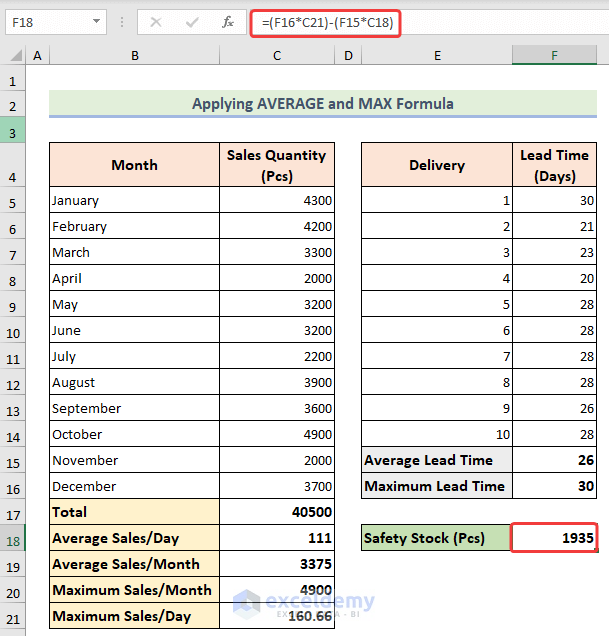

Image:

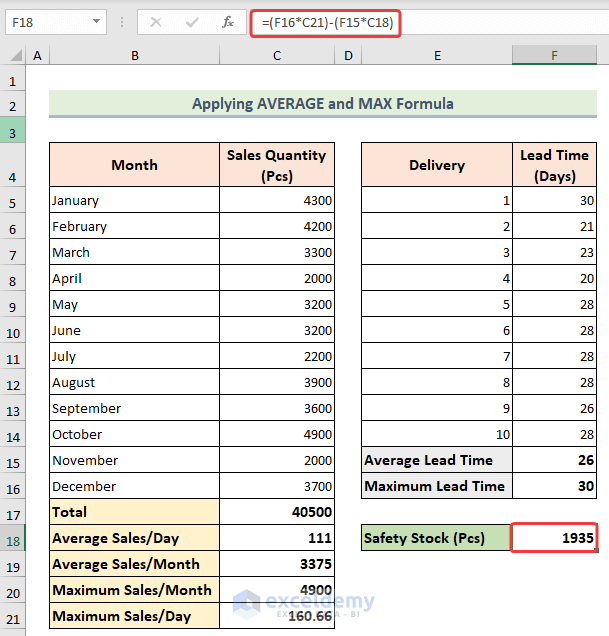

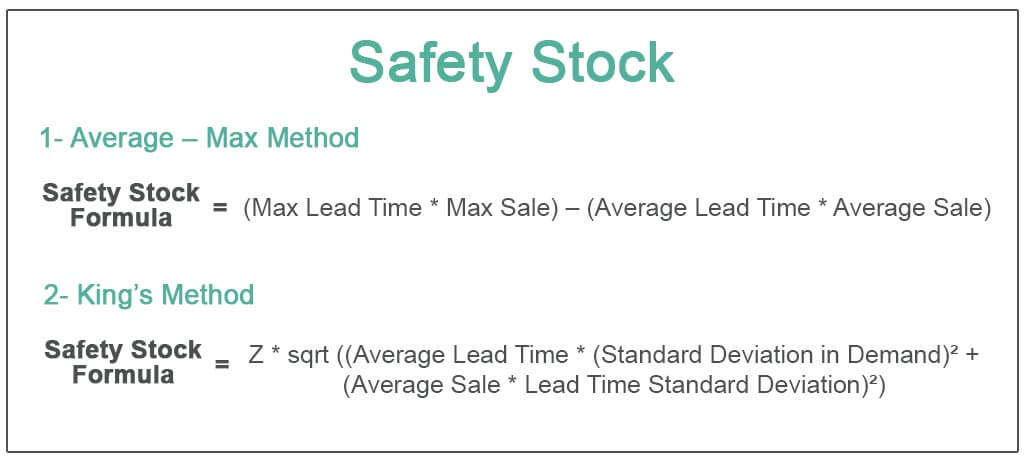

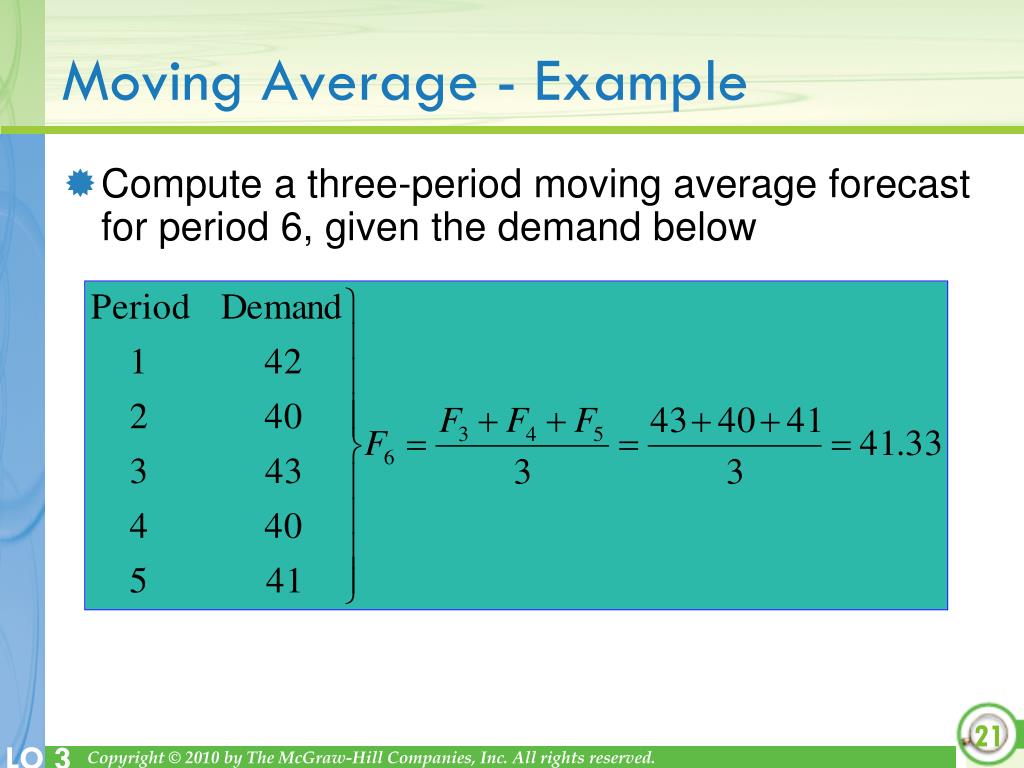

Method 4: Moving Average-Based Safety Stock Calculation

This method involves using a moving average of historical demand data to calculate safety stock.

Formula: Safety Stock = (Moving Average of Demand x Lead Time) x (1 + (Standard Deviation of Demand / Average Demand))

Example:

| A | B | C | |

|---|---|---|---|

| 1 | Moving Average of Demand | 12 | |

| 2 | Standard Deviation of Demand | 2 | |

| 3 | Lead Time (days) | 5 | |

| 4 | Safety Stock | =(A1*C1)*(1+(B1/A1)) |

Using this formula, the safety stock would be 60 units.

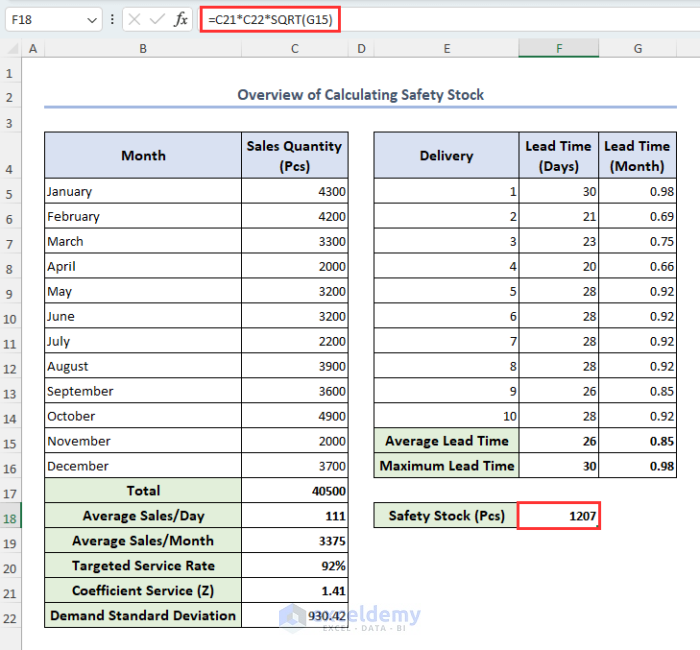

Image:

Method 5: Machine Learning-Based Safety Stock Calculation

This method involves using machine learning algorithms to analyze historical demand data and calculate safety stock.

Formula: Safety Stock = (Predicted Demand x Lead Time) x (1 + (Standard Deviation of Demand / Average Demand))

Example:

| A | B | C | |

|---|---|---|---|

| 1 | Predicted Demand | 15 | |

| 2 | Standard Deviation of Demand | 2 | |

| 3 | Lead Time (days) | 5 | |

| 4 | Safety Stock | =(A1*C1)*(1+(B1/A1)) |

Using this formula, the safety stock would be 75 units.

Image:

Conclusion

Calculating safety stock is a critical aspect of inventory management, and there are various methods to do so. In this article, we explored five ways to calculate safety stock in Excel, including basic, service level-based, historical data-based, moving average-based, and machine learning-based methods. By using these methods, businesses can ensure that they have sufficient stock to meet customer demand and mitigate the risk of stockouts and lost sales.

Gallery:

FAQs

Q: What is safety stock? A: Safety stock is a level of inventory that a business maintains to mitigate the risk of stockouts and lost sales.

Q: How do I calculate safety stock? A: There are various methods to calculate safety stock, including basic, service level-based, historical data-based, moving average-based, and machine learning-based methods.

Q: What is the importance of safety stock? A: Safety stock is important because it ensures that a business has sufficient stock to meet customer demand in case of supply chain disruptions or changes in demand.

Q: How do I determine the optimal safety stock level? A: The optimal safety stock level depends on various factors, including the desired service level, lead time, and demand variability.

Q: Can I use machine learning algorithms to calculate safety stock? A: Yes, machine learning algorithms can be used to analyze historical demand data and calculate safety stock.