Effective equipment maintenance is crucial for ensuring the longevity and efficiency of industrial equipment, as well as the safety of workers and the overall productivity of an organization. A well-planned maintenance strategy involves regular inspections, routine maintenance tasks, and timely repairs to prevent equipment breakdowns. One of the most efficient ways to manage equipment maintenance is by using an equipment maintenance log template, preferably in Excel, due to its versatility and widespread use.

The Importance of Equipment Maintenance Logging

Equipment maintenance logging is a systematic approach to tracking and managing the maintenance activities performed on equipment. This logging is essential for several reasons:

- Prevents Equipment Downtime: By performing maintenance tasks on time, you can significantly reduce the likelihood of equipment failures and the resulting downtime.

- Improves Safety: Regular maintenance helps in identifying potential safety hazards and correcting them before they lead to accidents.

- Enhances Equipment Life: Proper maintenance extends the operational life of equipment, reducing the need for premature replacements.

- Reduces Maintenance Costs: Regular maintenance can help in early detection of issues, reducing the need for costly repairs.

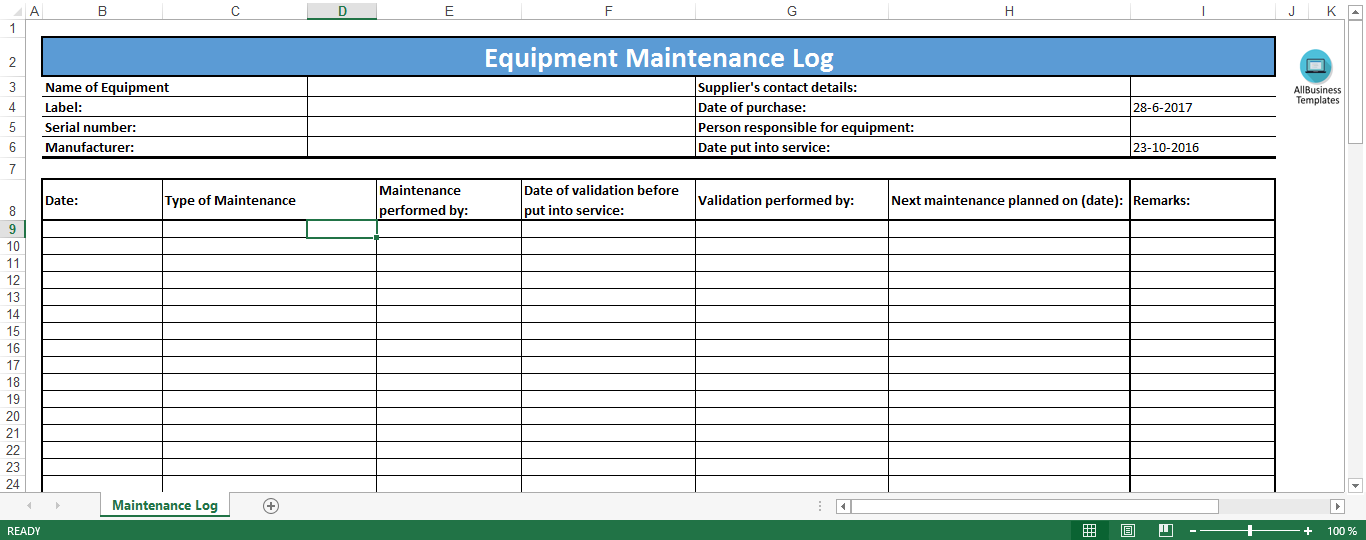

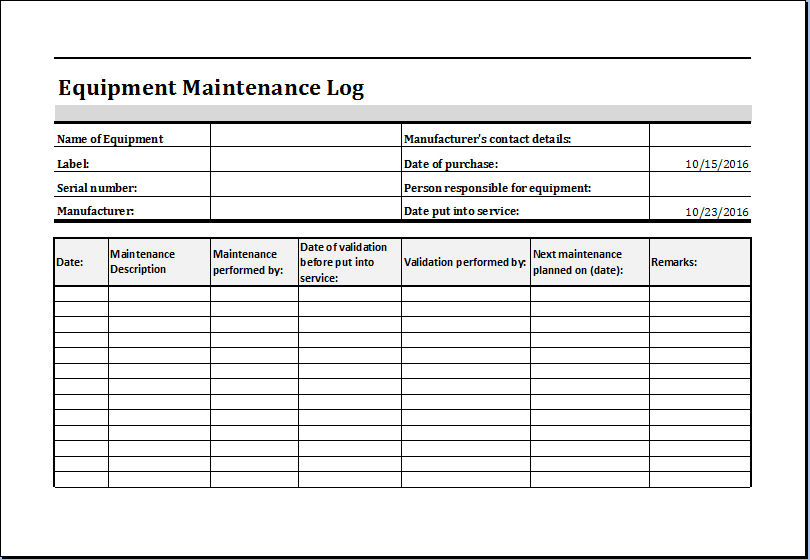

Creating an Equipment Maintenance Log Template in Excel

While there are numerous software solutions available for maintenance logging, an Excel template remains a popular choice due to its ease of use, customization, and accessibility. Here’s a step-by-step guide to creating a basic equipment maintenance log template in Excel:

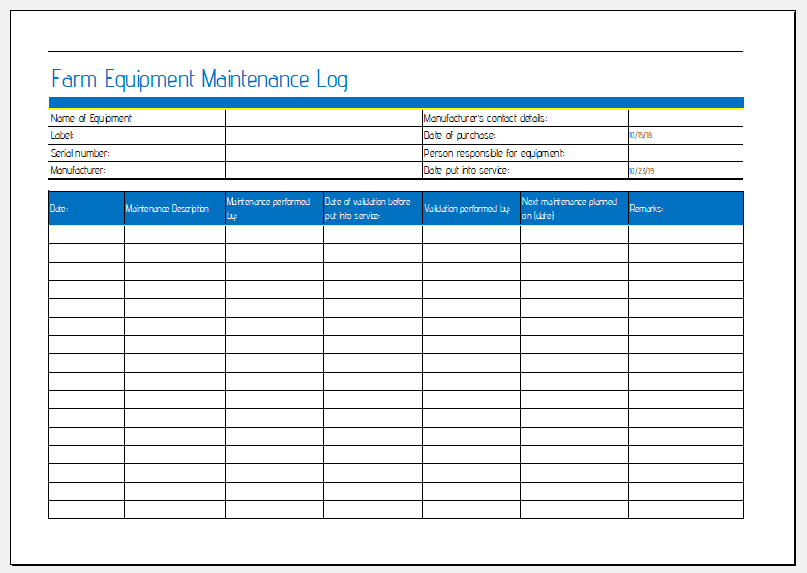

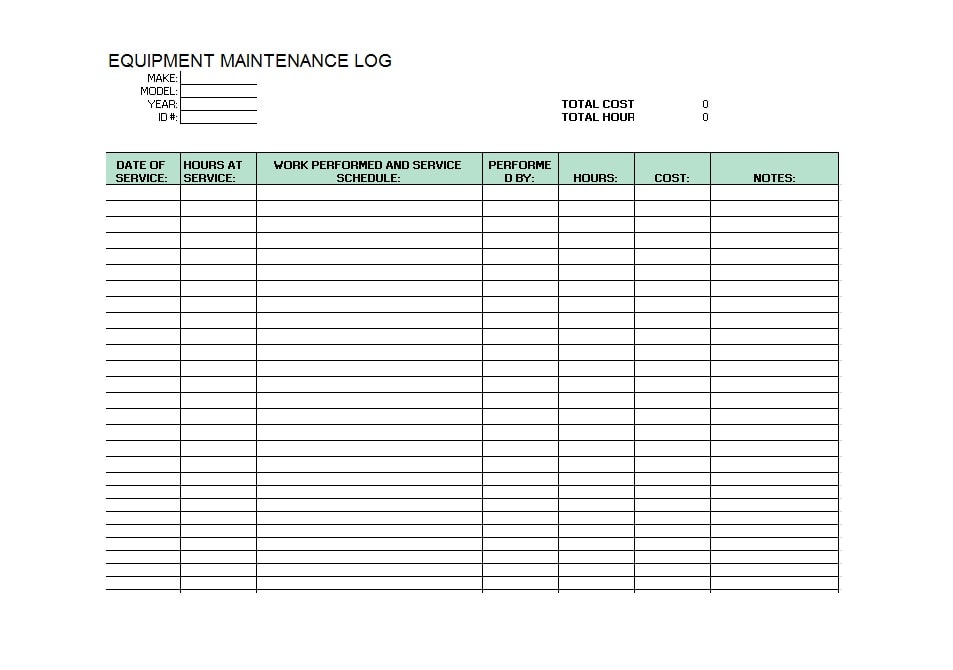

Step 1: Setting Up the Template Structure

- Equipment Details: Include columns for equipment name, model number, serial number, and location.

- Maintenance Type: Differentiate between routine, corrective, and preventive maintenance tasks.

- Date and Time: Record the date and time of the maintenance activity.

- Task Description: A brief description of the maintenance task performed.

- Parts Used: List any parts or materials used for the maintenance.

- Performed By: Record the name or ID of the person performing the maintenance.

- Next Scheduled Maintenance: Schedule the next maintenance activity.

Step 2: Customizing the Template

- Add Conditional Formatting: Use conditional formatting to highlight upcoming or overdue maintenance activities based on the next scheduled maintenance date.

- Create Drop-down Lists: For columns like maintenance type, make drop-down lists to ensure uniformity in data entry.

- Use Auto-filters: Enable auto-filters to make sorting and filtering data easier.

Step 3: Integrating Advanced Features

- Calendar View: Create a calendar view of maintenance activities to have a visual representation of upcoming tasks.

- Alert System: Set up an alert system, either through Excel’s built-in features or through integration with other tools, to notify maintenance personnel of upcoming tasks.

Step 4: Implementing and Monitoring

- Train Personnel: Ensure that all maintenance personnel are trained on using the template.

- Regular Reviews: Conduct regular reviews of the maintenance log to identify trends, areas of improvement, and the effectiveness of the current maintenance strategy.

Conclusion

An equipment maintenance log template in Excel is a simple yet effective tool for managing equipment maintenance activities. Its customization capabilities, ease of use, and the ability to integrate advanced features make it an indispensable tool for industries of all sizes. By implementing such a system, organizations can move towards a more proactive maintenance strategy, reducing downtime, improving safety, and enhancing the operational efficiency of their equipment.

Gallery of Equipment Maintenance Management

FAQs

What is the primary goal of using an equipment maintenance log template?

+The primary goal is to systematically track and manage maintenance activities to reduce equipment downtime and improve operational efficiency.

Why is Excel a popular choice for creating maintenance log templates?

+Excel is widely used due to its ease of use, customization capabilities, and accessibility.

How can an equipment maintenance log template help in cost reduction?

+It helps in early detection of issues, reducing the need for costly repairs and extending the operational life of equipment.